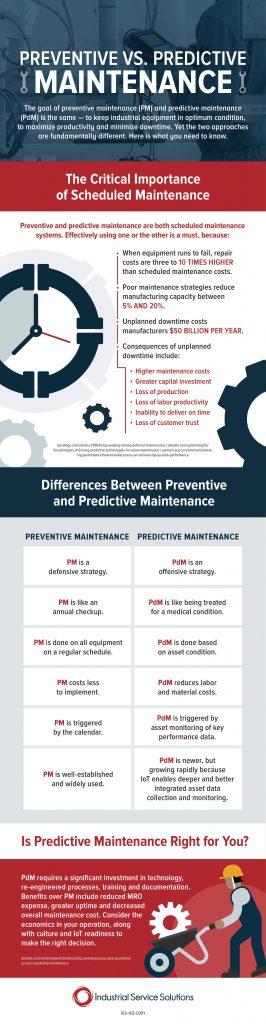

The way in which organizations conduct maintenance for their manufacturing equipment varies per organization. In most cases, a majority of organizations default to the preventive maintenance approach. However, some organizations opt to utilize the predictive maintenance approach, which is much more sophisticated.

Preventive maintenance is a long-standing strategy in the manufacturing industry. This strategy is rather simple: schedule routine maintenance to each individual piece of manufacturing equipment within an operation, be it the Industrial Vibratory Conveyor, Casting Coolers, Hydraulic lift, or any other equipment for that matter, and perform maintenance on them at those scheduled intervals. Some intervals will be different for different sets of equipment. For example, older pieces of equipment may require additional maintenance than newer pieces of equipment over the same time period. As such, the intervals for these older pieces of equipment may be shorter than the newer pieces of equipment in a particular operation. The same could potentially be said for pieces of equipment that see more use than other pieces of equipment. If you have an industrial surplus (in regards to equipment) it may be worth carrying out basic maintenance and selling.

A newer, much more sophisticated strategy for maintenance is predictive maintenance. In contrast to preventive maintenance, rather than having set scheduled intervals, why not let the machines notify you when industrial hardware requires maintenance? This is the approach of predictive maintenance. Through highly integrated systems, organizations are able to monitor important precursor data that would indicate when a piece of industrial equipment would require maintenance. Seems perfect, right? This could especially come in handy for the oil and gas industry, wherein the regular maintenance of pipelines is important for preventing leaks. With the technique of predictive maintenance, the authorities would be notified when the pipes need upkeep, after which they can use a double block & bleed valve to bleed any pressure that remains in the pipe so that it can be isolated for maintenance. Though this might sound great the systems that are needed to be installed for performing predictive maintenance aren’t cheap. The good news is that they typically cost about the same as preventative maintenance. So, those who are into the latter can switch to predictive upkeep.

In any case, as mentioned previously, most business owners are aware that transitioning to a predictive maintenance strategy is quite challenging. Not only do these systems cost an exuberant amount of capital, but they also require a highly customized set of training protocols that organizations must educate their employees on. No matter the status of your organization, this can be challenging. Whether it be trying to teach long-standing employees new systems and protocols that go against everything they may’ve known previously in their time with an organization, or new employees completely unaware of what they’re getting themselves into, you’re bound to face some challenges. Regardless of this, if your organization has the available capital to invest in these systems, it is worth the investment. While the training might not be easy, your employees will eventually transition more smoothly and the benefits would outweigh the costs.

If your business is currently considering the switch, be sure to review the featured resource below for more information regarding predictive and preventive maintenance. The infographic contains additional details regarding the advantages and disadvantages of each approach, and what that can mean for your business. All courtesy of Industrial Service Solutions.